THE UKs LEADING EXPERTS

Production stopped because of a belt failure? Every minute costs you money.

We're engineers, not just suppliers. That means we identify the right belt fast, solve underlying mechanical issues, and get you back to full operation. As the UK's official Nitta Partner, we combine Japanese precision engineering with local expertise and rapid response.

Whether you need same-day delivery from our extensive stock or expert fitting to prevent future problems, we've got your back.

Approved Nitta Partner

As Nitta's approved UK partner, we bring you direct access to their technical excellence. That means longer belt life, fewer failures, and specifications engineered for precision applications.

Nitta Corporation engineers some of the world's most advanced conveyor and machine belts. Their PolySprint series dominates printing presses globally. Their NLG belts handle the toughest warehouse operations.

We don't just stock Nitta belts - we understand how they perform in real-world conditions.

BELT applications

BELTS FOR ALL SECTORS

Different industries demand different belt specifications. Hygiene standards for food. Fire-retardant materials for aviation. Precision tracking for print.

We understand sector-specific requirements because we've worked across them all. Click your industry to see how we solve the belt challenges you face.

Print industry conveyor belts demand precision and gentle handling. Whether you're feeding paper through litho presses, running digital machines, or transporting printed materials through finishing equipment, these belts need anti-static properties, non-marking surfaces, and dimensional stability for accurate registration.

TESTIMONIAL

Paul and Alan have been supporting our site here in Newmarket for the last 25 years. Within this time we as a company have built up a fantastic working relationship and support network with APR. Which benefits our site not only with servicing contracts and breakdown cover but more importantly, the technical support, their knowledge and experience is only an email or phone call away. APR have been integral in our development of the new Pratham lines that our site has invested in, giving constant support when required. We all wish this collaboration to carry this site to the next level.

MM Packaging UK Limited

Dave Dobbyn - Production Manager

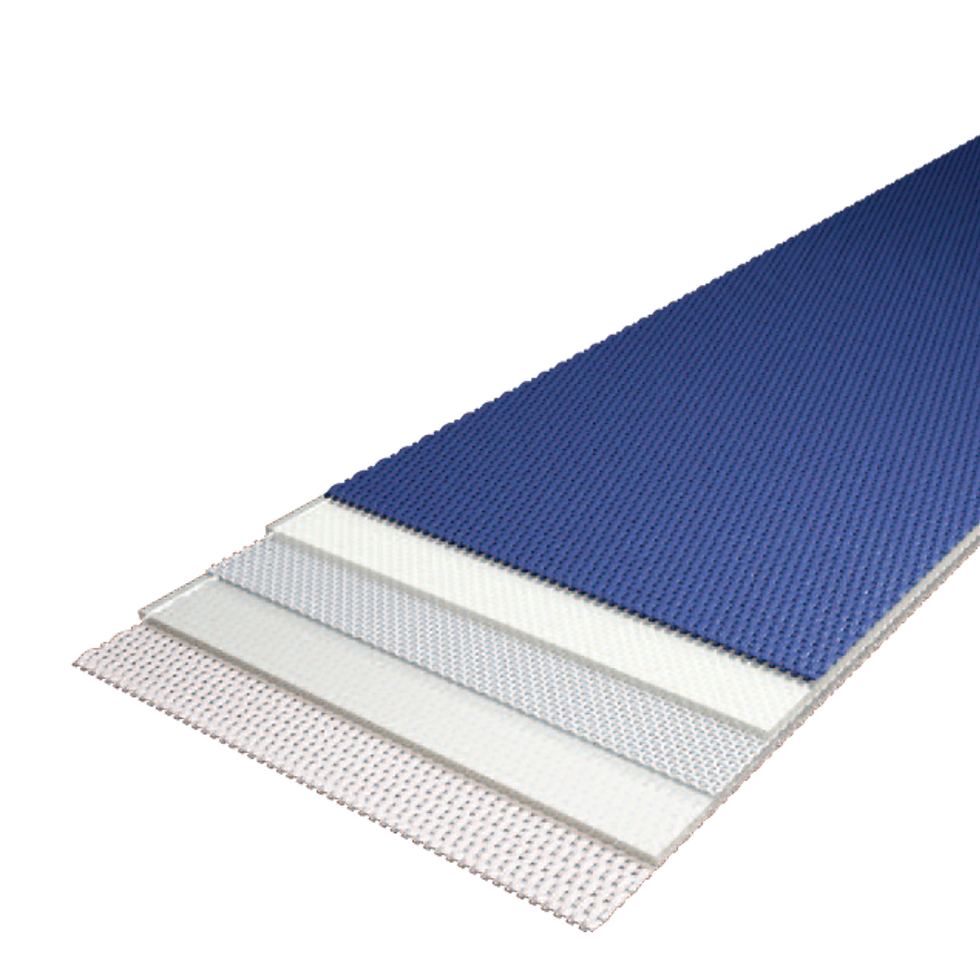

BELT MATERIALS

Choosing the right belt material makes the difference between reliable performance and premature failure.

Your application determines whether you need PVC for flexibility, polyurethane for abrasion resistance, rubber for grip, or specialist materials like Teflon, silicon, or aramid for extreme conditions. We don't guess - we match material properties to your operating environment.

ABOUT APR

Over 80 years of combined engineering experience means we've seen every belt problem there is.

We are a business built on solving problems properly. That means honest advice, fast response times, and engineering solutions that last. When we fit a belt, we check for underlying issues - seized bearings, misalignment, contamination - because we're invested in fixing your problem, not just making a sale.

ABOUT NITTA

Nitta Corporation has manufactured precision belts since 1885. Their research facilities in Japan develop materials that outlast competitor products by factors of two to three times.

Global companies to name a few like Komori, Bobst and Muller Martini specify Nitta belts as original equipment. Major warehouse automation suppliers partner with Nitta for their conveyor systems. That's the quality we bring you.

.png)

.png)