MARINE & SEAFOOD INDUSTRY BELTS

Find Your MARINE OR SEAFOOD Belt

Coastal operations push conveyor belts to their limits. Saltwater spray corrodes standard components within months. Fish oils penetrate unsealed edges and delaminate belt layers. Constant washdowns with chlorine-based sanitisers attack materials that work fine in dry environments. Whether you're processing fish at a harbour facility, running seafood packing lines, or managing port cargo operations, you need belts engineered for these punishing conditions.

As the UK's official Nitta Partner, APR Conveyor Belts supplies specialist belts for marine and seafood applications. We understand the hygiene requirements of fish processing, the corrosion challenges of coastal environments, and the need for fast supply when your production line stops.

Not sure which belt specification suits your application? Got an existing belt that's failing prematurely in wet conditions? Our APR Belt Finder tool helps you identify the right belt for fish processing lines, seafood grading systems, or port conveyor applications. Tell us about your environment - what you're handling, your cleaning regime, temperature exposure - and we'll match you to the appropriate Nitta specification. If you're replacing a competitor belt from Forbo, Habasit, or Chiorino, we'll cross-reference to identify the correct equivalent. Can't find what you're looking for? Give us a call and we'll sort it for you.

Marine and Seafood Applications

Conveyor belts serve critical functions throughout coastal industries, each with specific material and design requirements:

Fish Processing Lines:

From quayside reception through to frozen dispatch, fish processing demands hygienic belt surfaces that handle constant water exposure. Filleting stations, skinning machines, and trimming lines need belts that maintain positioning accuracy whilst withstanding fish oils and regular sanitisation.

Seafood Grading and Sorting:

Mechanical graders separating catch by size require belts with appropriate friction properties and drainage capability. High-throughput operations handling tonnes per hour need dimensional stability and reliable tracking in wet conditions.

Freezing and Cold Storage:

IQF tunnel freezers operating at -40°C demand belts that maintain flexibility at extreme low temperatures. Standard materials become brittle and crack - specialist compounds handle continuous operation in frozen environments.

Harbour and Port Operations:

Dockside conveyor systems face saltwater spray, humidity fluctuations, and exposure to oils and greases. Cargo handling operations need robust belts that resist the accelerated corrosion coastal environments create.

Aquaculture and Fish Farming:

Feed handling systems, fish grading equipment, and harvesting conveyors in marine and brackish water environments require corrosion-resistant materials with extended service intervals for remote locations.

Typical Seafood Processing Applications

Conveyor belts are critical throughout fish and seafood processing operations:

Reception and Unloading:

Quayside conveyors handling boxes and loose catch from vessels, withstanding abrasion from sand, grit, and saltwater.

Washing and Rinsing:

Perforated belts providing drainage between processing steps, handling constant water immersion.

Grading and Sorting:

Mechanical graders with appropriate friction surfaces, separating catch into size categories.

Filleting and Processing:

Precision positioning for automated cutting equipment, non-stick surfaces for product release.

Inspection Systems:

X-ray and detection equipment requiring metal-free belt components and homogeneous surfaces.

Freezing Lines:

IQF tunnel freezers with temperature-resistant modular belts, spiral configurations maximising space efficiency.

Packing and Despatch:

Final handling requiring gentle product contact and hygienic surfaces.

Identifying the correct belt for your specific press doesn't have to be complicated. Our APR Conveyor Belts Belt Finder tool streamlines the selection process, helping you quickly locate the right belt based on your machine type, application requirements, and material specifications. Simply input your press details or upload a photo of your existing belt, and we'll match you with the optimal Nitta solution -ensuring you get the right belt first time, every time.

TESTIMONIAL

Paul and Alan have been supporting our site here in Newmarket for the last 25 years. Within this time we as a company have built up a fantastic working relationship and support network with APR. Which benefits our site not only with servicing contracts and breakdown cover but more importantly, the technical support, their knowledge and experience is only an email or phone call away. APR have been integral in our development of the new Pratham lines that our site has invested in, giving constant support when required. We all wish this collaboration to carry this site to the level.

MM Packaging UK Limited

Dave Dobbyn - Production Manager

Belt Requirements for Marine Environments

Coastal and marine applications demand specific performance characteristics that standard industrial belts cannot deliver:

Corrosion Resistance:

Saltwater concentrations of 3-4% accelerate electrochemical corrosion on standard metal components. Marine applications need stainless steel fasteners (316 grade minimum), non-metallic alternatives where possible, and materials that withstand chloride attack.

Wet Environment:

Performance Constant moisture causes friction-driven belts to slip and lose tracking. Positive-drive sprocket systems and V-guided tracking eliminate these problems. Sealed edges prevent water ingress that leads to delamination.

Chemical Resistance:

Fish processing uses chlorine-based sanitisers (50-200ppm), peracetic acid, quaternary ammonium compounds, and sodium hydroxide cleaners. Belt materials must withstand repeated exposure without degradation. Fish oils penetrate and swell unsuitable materials.

Temperature Range:

Operations span from freezer environments at -40°C through to ambient coastal conditions with humidity fluctuations. Materials must maintain flexibility and performance across this entire range.

Hygiene Compliance:

Food contact applications require FDA 21 CFR 177.2600 and EU 10/2011 compliance. HACCP-compatible designs with sealed edges, rounded corners, and easy-clean surfaces are essential for audit readiness.

Geographic Coverage

We supply and support marine and seafood operations throughout the UK's coastal regions:

Scotland Peterhead, Fraserburgh, Aberdeen, Shetland, and salmon processing facilities.

Humber Region Grimsby, Hull, and the UK's largest fish processing hub.

South West Cornwall, Brixham, Plymouth, and Devon's fishing communities.

East Anglia Lowestoft, Great Yarmouth, and Norfolk's seafood industry.

Major Ports ABP terminals, Peel Ports facilities, and cargo handling operations nationwide.

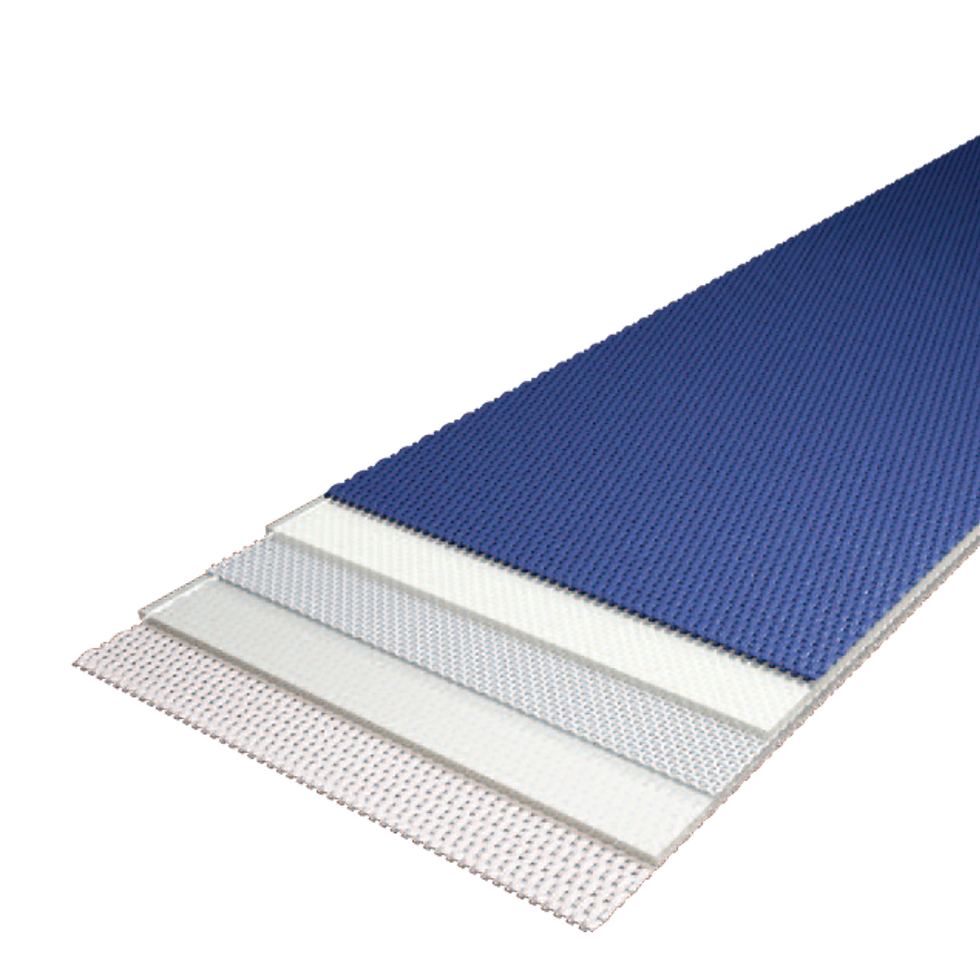

Nitta Belt Series for Marine Applications

Food-Grade Conveyor Belts:

Nitta's food-grade range meets FDA and EU compliance requirements for direct seafood contact. Sealed edge construction prevents bacterial harbourage. Available in white and blue colours, standard in fish processing environments.

Cold-Resistant Belts:

Specialist compounds maintain flexibility and performance in freezer environments. TPU formulations for cold storage handling, modular plastics for IQF tunnel freezers operating continuously at -40°C and below.

Wet Environment Belts:

Positive-drive constructions with sprocket engagement for reliable operation in constantly wet conditions. V-guided tracking systems maintain belt position where standard friction-drive systems fail.

Why Choose APR & Nitta for Marine and Seafood Belts

Nitta Corporation has developed specialist belt materials for demanding wet environments and food processing applications. Their research facilities in Japan engineer compounds that resist the specific challenges marine operations create - saltwater exposure, fish oil penetration, chemical cleaning regimes, and temperature extremes.

As the UK's official Nitta Partner, APR Conveyor Belts combines this technical excellence with local expertise and rapid supply capability. We understand that seafood processing runs on tight schedules - fish doesn't wait while you source replacement belts. Our engineering approach means we solve problems, not just supply products.

Companies We Supply

APR supplies conveyor belts to fish processors, seafood packers, and coastal operations across the UK. We work with maintenance engineers, production managers, and facilities teams who need reliable belt supply without delays. Whether you're running a fish processing facility in Grimsby, managing salmon packing lines in Scotland, or maintaining port conveyor systems, we provide the same fast response and technical expertise our customers depend on.

Common Questions About Marine and Seafood Conveyor Belts

TPU (thermoplastic polyurethane) delivers the best all-round performance for fish processing - excellent resistance to fish oils and fats, maintains flexibility in cold environments, and withstands repeated cleaning with sanitising chemicals. FDA-compliant formulations are available for direct food contact. For freezer applications below -30°C, modular plastic belts using POM or PE materials provide reliable performance.

Three key factors: use positive-drive or V-guided tracking systems rather than friction-drive (which slips when wet), specify belts with sealed or moulded edges to prevent water ingress and delamination, and ensure all metal components are marine-grade stainless steel (316 minimum). Regular inspection of splice integrity is essential in wet environments.

Food contact applications require FDA 21 CFR 177.2600 compliance (US) and EU 10/2011 certification (UK/EU). Many processors also require HACCP-compatible designs and may need to demonstrate compliance with BRC Global Standards for retail supply. We can provide documentation for all Nitta food-grade products.

Yes. Blue has become the standard colour in fish and seafood processing because it's easily visible if belt fragments contaminate product. Nitta supplies food-grade belts in blue as standard for seafood applications.

Fish processing belts need enhanced resistance to fish oils and fats (which can penetrate and swell standard materials), better performance in constantly wet conditions, and often require low-temperature flexibility for chilled and frozen handling. Standard food-grade belts designed for dry packaged goods won't survive the harsh conditions fish processing creates.

Yes. We supply conveyor belts for dockside operations, cargo handling, and port facilities. These applications need corrosion-resistant materials and robust construction rather than food-grade compliance. Contact us with your specific requirements - bulk handling, container terminals, or general cargo operations.

belt problems?

Processing line down? Seafood spoiling while you wait for parts? Contact APR Conveyor Belts for expert belt identification, rapid supply of marine and seafood specifications, and technical support that understands your industry.

.png)