PRINT INDUSTRY BELTS

Find Your Print Belt

As the UK's official Nitta Partner, we provide next-day delivery on common stock. Our engineering team identifies the correct belt specification, cross-references alternatives, and offers installation services to minimise downtime.

Reliable stock levels and technical support for both end users and resellers.

Typical Print Applications

As the UK's official Nitta Partner, we provide next-day delivery on common stock. Our engineering team identifies the correct belt specification, cross-references alternatives, and offers installation services to minimise downtime.

Reliable stock levels and technical support for both end users and resellers.

Litho Printing Presses

Feeding and transporting sheets through multi-colour offset presses where registration accuracy is critical

Digital Printing Equipment

Supporting sheet and web-fed digital presses with precise paper handling and minimal static generation

Finishing Operations

Moving printed materials through folding, creasing, and trimming processes

Binding Equipment

Conveying signatures and book blocks through stitching, perfect binding, and case-making machinery

Folder Gluers

Transporting flat cartons through folding and gluing sections for packaging production

Postal & Mailing Systems

Handling envelopes and direct mail pieces through sorting and insertion equipment

Identifying the correct belt for your specific press doesn't have to be complicated. Our APR Conveyor Belts Belt Finder tool streamlines the selection process, helping you quickly locate the right belt based on your machine type, application requirements, and material specifications. Simply input your press details or upload a photo of your existing belt, and we'll match you with the optimal Nitta solution -ensuring you get the right belt first time, every time.

TESTIMONIAL

Paul and Alan have been supporting our site here in Newmarket for the last 25 years. Within this time we as a company have built up a fantastic working relationship and support network with APR. Which benefits our site not only with servicing contracts and breakdown cover but more importantly, the technical support, their knowledge and experience is only an email or phone call away. APR have been integral in our development of the new Pratham lines that our site has invested in, giving constant support when required. We all wish this collaboration to carry this site to the level.

MM Packaging UK Limited

Dave Dobbyn - Production Manager

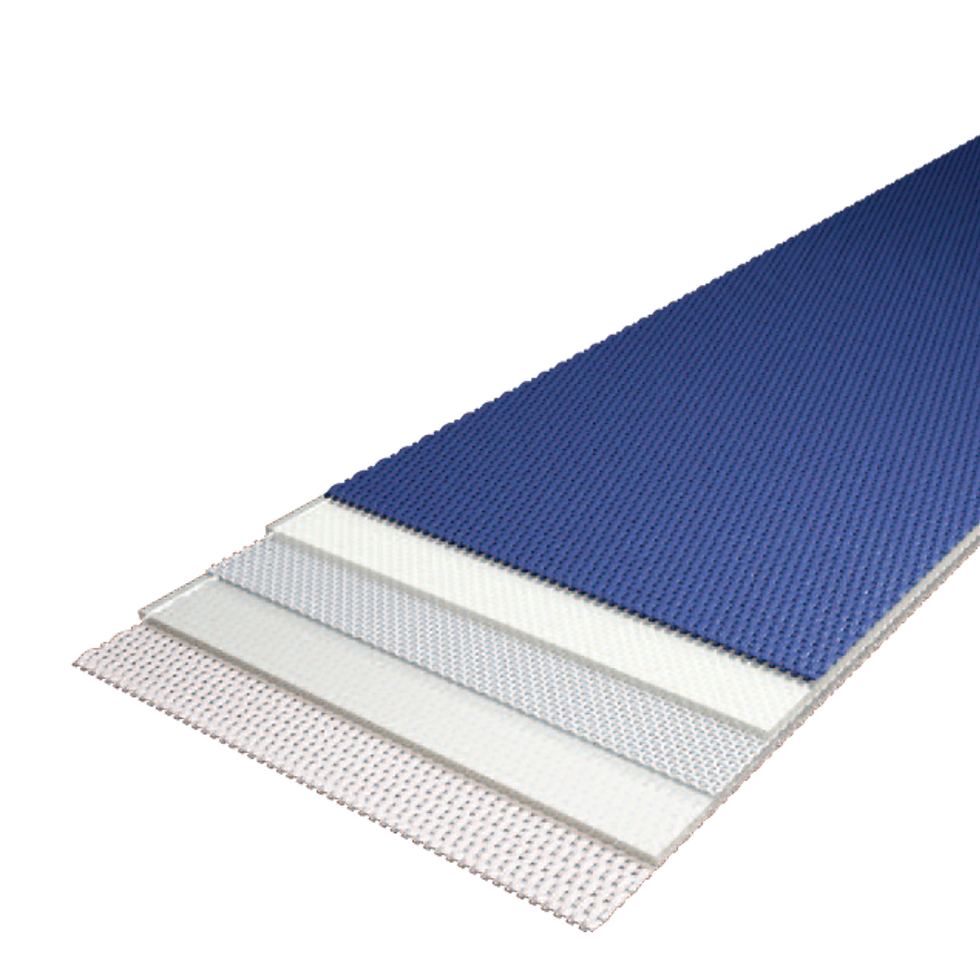

Types of Material Properties

Print applications demand specific belt characteristics to maintain quality and prevent damage. The most critical properties for printing industry belts include:

-

Anti-static properties – Essential for preventing static buildup that causes dust attraction, sheet adhesion, and ink tracking

-

Non-marking surfaces – Crucial to avoid ink transfer or surface damage on printed materials

-

Dimensional stability – Maintains registration accuracy across long production runs

-

High friction coefficient – Ensures reliable sheet separation and controlled feeding

-

Gentle handling – Protects delicate coated papers and specialty substrates

Selecting the right belt material directly impacts print quality, production efficiency, and operational costs. The wrong material can cause marking, registration drift, static-induced defects, and premature belt failure—all of which result in costly downtime and wasted materials.

Thermoplastic Polyurethane

(TPU)

Highly durable material that resists wear from constant use and stands up to inks and cleaning chemicals. TPU belts won't stretch over time, maintaining precise registration, and their smooth surfaces won't mark your paper—ideal for high-speed feeder and transport applications where accuracy and long belt life matter.

Nitrile Rubber

(NBR)

Provides exceptional grip for reliable sheet pickup and separation whilst resisting oils and inks. The surface maintains consistent friction even after exposure to printing chemicals, making it perfect for feeder belts where you need dependable paper handling to prevent double-feeding and keep production running smoothly.

Special Polyamide

Fabric

Exceptionally gentle on paper with a soft touch that won't mark even delicate coated stocks. This material is specifically designed to handle freshly printed sheets without damaging the surface or transferring ink—the go-to choice when print quality and substrate protection are non-negotiable.

Elastic TPU

Compounds

Flexible material that grips paper gently without needing complex tensioning systems. It adapts to different paper thicknesses whilst maintaining steady contact, making it ideal for bookbinding equipment and postal machines where you need reliable handling across varied materials.

Polyester and Aramid

Core Materials

Reinforcement materials that virtually eliminate stretching under load, keeping your multi-colour registration spot-on throughout production runs. Aramid cores are particularly stable, maintaining tight tolerances essential for high-quality commercial printing where even tiny shifts affect final print quality.

Print Machines We Supply Belts For:

We provide belts for a range of printing and bookbinding equipment, providing belt solutions across the full spectrum of print industry machinery.

-

Heidelberg offset presses

-

KBA litho and digital presses

-

Komori sheet-fed presses

-

Manroland web and sheet-fed systems

-

Roland printing equipment

-

Folder gluers and die-cutting machines

-

Perfect binding and saddle-stitching lines

-

Newspaper and magazine production lines

-

Finishing and converting equipment

Nitta Corporation brings 140 years of belt technology expertise with specialised belt series engineered for demanding print applications. As the UK's official Nitta Partner, APR Conveyor Belts combines this excellence with over 100 years of combined experience in the print industry. We're engineers who solve problems, not just belt suppliers—we give you the peace of mind that comes from working with people who have got your back.

Common Questions About Print Belts and APR Conveyor Belts Services

Feeder belts (also called feed tapes or feed bands) operate at the input section of your press, transporting sheets from the pile table through the feedboard to the press in-feed. Their main job is precise sheet separation and controlled paper handling - working with vacuum suckers and air blasts to separate individual sheets whilst maintaining consistent spacing. They need high friction for reliable grip and must prevent double-feeding to ensure sheets arrive at the front guides with exact timing for proper registration.

Transport belts (or delivery belts, sometimes called slow-down belts) work at the output section, conveying printed sheets from the final printing unit to the stacking area. These belts must handle wet ink without marking, control sheet deceleration for proper pile formation, and support organised stacking with correct alignment. The critical challenge is avoiding contact with freshly printed surfaces whilst maintaining controlled movement speeds—typically running at deliberately reduced velocities to facilitate proper sheet separation in the delivery pile.

Super Endless Belts (SEB) represent the premium choice for feeder applications requiring ultimate precision. These truly seamless belts eliminate splice points entirely, removing periodic variations that even well-made splices introduce. For high-end commercial printing and publication work where registration tolerances reach ±0.05mm or tighter, SEB technology provides zero registration variations from belt joints. Alternatively, PolySprint FZ-5E12 with special polyamide fabric offers excellent all-round performance with built-in anti-static properties and finger-spliceable convenience for operations prioritising maintenance efficiency.

Response time depends on the belt type and specific problem, but we always prioritise getting you back into production quickly. For common printing belt specifications, we offer *same day and next-day delivery from stock. When specialist belts require ordering, our belt engineers can often advise temporary solutions to maintain production whilst the correct belt is sourced. We understand that machine downtime costs money and damages customer relationships - we treat your emergency as our priority, providing both immediate support and long-term solutions.

Yes, we supply the complete range of Nitta endless belt solutions for printing applications. This includes PolySprint finger-spliceable belts that can be joined on-site in minutes without adhesives, PolyBelt skive-splice constructions for precision applications, and seamless Super Endless Belts (SEB) manufactured in Japan for ultimate performance. We work with you to determine which endless belt technology best matches your specific press requirements, quality standards, and maintenance capabilities.

Absolutely. Our technical team can cross-reference belt codes from other suppliers to identify equivalent or superior Nitta alternatives. Provide us with your existing belt code, press model, or simply upload a photo of your current belt, and we'll match it with the appropriate Nitta specification. In many cases, we can recommend upgraded materials that offer longer service life, better performance, or improved anti-static properties compared to your existing belt—helping you reduce replacement frequency and improve print quality.

Belt marking typically results from several factors: improper material selection (belts without non-marking surfaces), contamination from ink buildup or debris, incorrect tensioning causing excessive pressure, or worn belts with glazed or damaged surfaces. Nitta belts designed for printing applications incorporate non-marking surface formulations specifically to prevent transfer. We address marking problems systematically - identifying the root cause, recommending appropriate material specifications (such as special polyamide fabric surfaces or PTFE-coated variants), and ensuring proper installation with correct tension and tracking.

Print Resources

Nitta Corporation provides comprehensive technical resources to support printing operations. Download detailed product catalogues featuring the complete PolyBelt, PolySprint, and NLG series with specifications and application guides. Technical bulletins cover installation procedures, maintenance best practices, and troubleshooting guidance for common printing belt challenges.

belt problems?

Don't let your stress levels go through the roof. Contact us today for expert belt advice, rapid supply, and professional installation services that get you back into production fast.

.png)