PACKAGING INDUSTRY BELTS

Find Your PACKAGING Belt

As the UK's official Nitta Partner, we supply specialist belts for folder gluers, carton manufacturing, die cutting, and corrugated production lines. Our engineering team identifies the correct belt specification, cross-references alternatives, and offers installation services to minimise downtime.

Whether you're producing pharmaceutical boxes, food packaging, or corrugated cartons, we've got the expertise and stock to keep your lines running.

Typical Print Applications

Not sure which belt you need for your folder gluer or carton line? Our APR Belt Finder tool streamlines the selection process, helping you quickly locate the right belt based on your machine type and application requirements. Simply input your equipment details or upload a photo of your existing belt, and we'll match you with the optimal Nitta solution.

Can't find what you're looking for? Give us a call and we'll sort it for you.

Belts are essential components throughout packaging operations, supporting precision and productivity across multiple applications:

Folder Gluers

Transporting flat cartons through folding and gluing sections, where belts handle prefold, bottom folding, final folding, and delivery operations

Corrugated Lines

Conveying corrugated cardboard through lamination, slitting, and stacking processes

Carton Erectors

Picking, opening, and forming flat cartons ready for product loading

Press Conveyors

Moving finished cartons through compression sections for proper adhesive setting

Identifying the correct belt for your specific press doesn't have to be complicated. Our APR Conveyor Belts Belt Finder tool streamlines the selection process, helping you quickly locate the right belt based on your machine type, application requirements, and material specifications. Simply input your press details or upload a photo of your existing belt, and we'll match you with the optimal Nitta solution -ensuring you get the right belt first time, every time.

TESTIMONIAL

Paul and Alan have been supporting our site here in Newmarket for the last 25 years. Within this time we as a company have built up a fantastic working relationship and support network with APR. Which benefits our site not only with servicing contracts and breakdown cover but more importantly, the technical support, their knowledge and experience is only an email or phone call away. APR have been integral in our development of the new Pratham lines that our site has invested in, giving constant support when required. We all wish this collaboration to carry this site to the level.

MM Packaging UK Limited

Dave Dobbyn - Production Manager

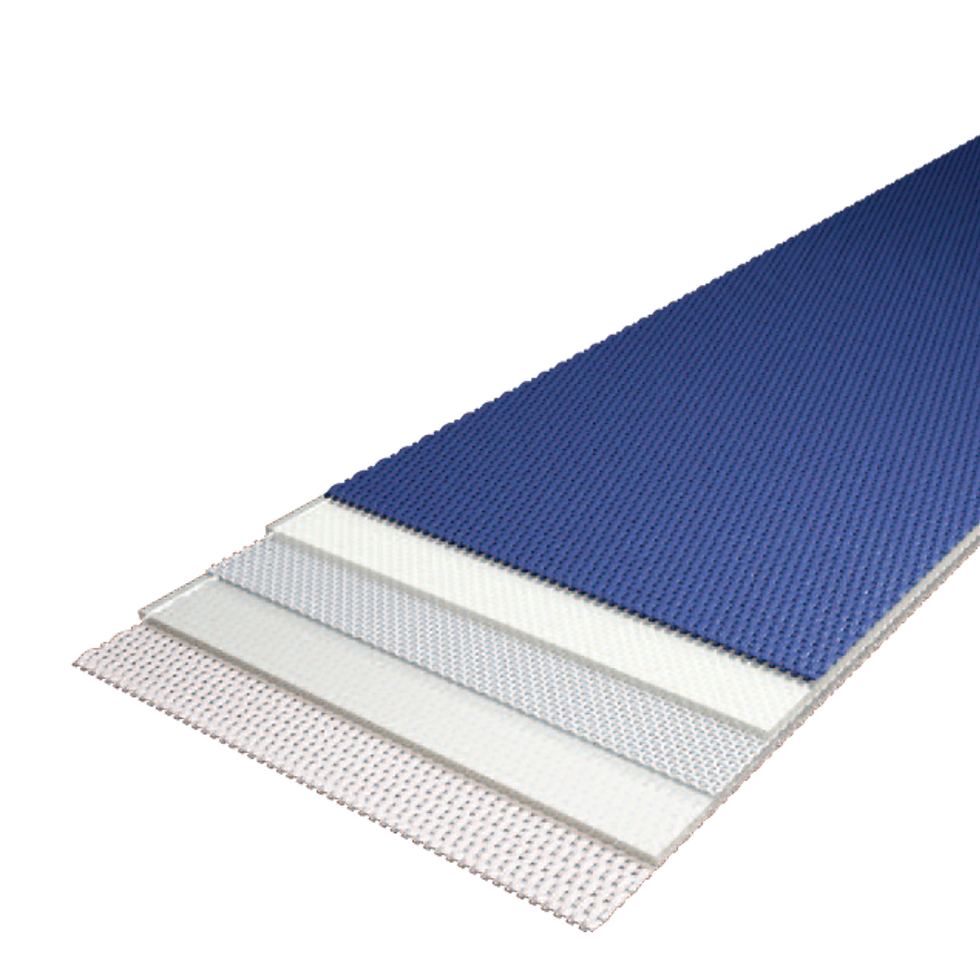

Belt Material Properties for Packaging

Packaging applications demand specific belt characteristics to handle varying carton textures, maintain production speeds, and ensure product quality:

-

High abrasion resistance – Essential for handling coarse corrugated materials and maintaining belt life across high-speed operations

-

High friction coefficient – Ensures reliable grip and conveyance capacity on rough top surfaces

-

Tear resistance – Critical for high-speed folder gluer operations where belts undergo constant stress

-

Dimensional stability – Maintains accuracy throughout long production runs and multiple bending cycles

-

Anti-static properties – Prevents dust attraction and product adhesion during carton handling

Flame retardant options – Available for environments with high cardboard dust concentrations

Nitrile Rubber

(NBR)

The go-to material for folder gluers and carton lines. Provides excellent grip with a stable friction coefficient, outstanding abrasion resistance, and high tear strength. The textured rough pattern surface handles everything from smooth paperboard to coarse corrugated materials.

Packaging Folder Gluer Machines We Supply Belts For:

We provide belt solutions across the full spectrum of packaging machinery:

-

Bobst folder gluers

-

Heidelberg carton manufacturing equipment

-

Jagenberg folding and gluing systems

-

Vega packaging machinery

-

Kama die cutting and finishing equipment

-

TCY carton manufacturing lines

-

Signature and Duran folder gluers

-

Corrugator stacking and material handling systems

-

Flexo folder gluer lines

-

Window patching and laminating machines

Why Choose APR Conveyor Belts for PACKAGING

Nitta Corporation brings over 140 years of belt technology expertise with specialised belt series engineered for demanding packaging applications. As the UK's official Nitta Partner, APR combines this engineering excellence with decades of hands-on experience in the packaging and print industries. We're engineers who solve problems, not just belt suppliers – we give you the peace of mind that comes from working with people who've got your back.

Our belts are trusted by major carton and corrugated manufacturers including operations supplied through DS Smith and WestRock facilities. Whether you need a single replacement belt or a complete set for a folder gluer line, we deliver the same fast response and technical expertise.

Belt Types for Packaging Operations

XH Series (PolyBelt and PolySprint):

Specifically designed for folder gluers, the XH-500 range handles prefold through to delivery sections. Available in 3mm to 6mm thicknesses with rough pattern NBR surfaces for reliable carton grip. The polyamide core provides high strength and excellent flange resistance for demanding folding operations.

RT and NRT Series (Rough Top):

All-round belts with stable friction coefficient and high abrasion resistance. The RT-300 and NRT-300 are workhorses for corrugator lines and carton manufacturing, suitable from corrugator discharge through to folder gluer operations. NRT-500 is specifically designed for lower folding sections.

SEB (Super Endless Belts):

Seamless integrally moulded belts for feeder sections. The seamless construction eliminates splice-related feeding variations, providing constant feeding power over extended periods. Ideal for folder gluer feeder sections where consistent sheet separation is critical.

NLG Wide Conveyor Belts:

Tough polyester canvas belts with low elongation for press conveyors, stackers, and material handling. Available in various widths, these belts provide rigidity in the width direction and flatness for corrugators and folder gluer press conveyor applications.

Common Questions About Packaging Belts

The XH-500 series is specifically engineered for folder gluer operations from prefold through to delivery sections. It features a polyamide core for high strength and excellent flange resistance during the twisting and bending that folder gluers demand. The RT-300 is a more versatile rough top belt designed for general carton and corrugated manufacturing applications, particularly suited to conveyors, squaring sections, and material handling where high abrasion resistance matters most.

Yes, Nitta produces FDA-compliant versions of the XH-500 series specifically for food and beverage packaging applications. These food-grade belts have very similar performance to the standard blue XH rubber whilst meeting extraction limits specified by the FDA. Nitta is one of the only manufacturers offering this option for folder gluer applications.

Response time depends on the belt type and specific problem, but we always prioritise getting you back into production quickly. For common packaging belt specifications, we offer same-day and next-day delivery for common stock . For less common specifications, we can typically source from Nitta as quick as seven to ten days.

A single folder gluer line can require 40 or more belts across the feeder, prefold, bottom folding, final folding, delivery, and press conveyor sections. We regularly supply complete belt sets for folder gluer refurbishments and can advise on the correct specifications for each section of your machine.

PACKAGING Resources

Nitta Corporation provides comprehensive technical resources to support packaging operations. Download detailed product catalogues featuring the complete PolyBelt, PolySprint, NLG, and SEB series with specifications and application guides. Technical bulletins cover installation procedures, maintenance best practices, and troubleshooting guidance for common packaging belt challenges.

belt problems?

Don't let your stress levels go through the roof. Contact us today for expert belt advice, rapid supply, and professional installation services that get you back into production fast.

.png)