Typical WAREHOUSE Applications

Warehouse and logistics operations rely on several conveyor configurations, each requiring specific belt types:

Flat Belt Conveyors Standard conveyor belts transporting parcels, boxes and packages across distribution centres. Available in various widths and specifications for different load capacities.

Live Roller Conveyors (Belt-Driven Rollers)

Belts driving roller beds underneath, allowing packages to sit on rollers whilst the belt provides the drive mechanism. Commonly uses CFTG series with aramid fibre construction.

Inclined/Declined Belt Conveyors

Transporting packages between floors or levels, requiring higher-friction ribbed surfaces to prevent slippage during elevation changes.

Cross-Belt Sorters

High-speed sortation systems with belts running perpendicular to the main conveyor direction, diverting packages to different destinations. Requires smooth, conductive surfaces like TA12 series.

Telescopic Belt Conveyors

Extendable conveyors for loading/unloading vehicles, using elastic/stretchy belt constructions to accommodate extension and retraction cycles.

(Note: We do not supply chain conveyors, slat conveyors, or modular plastic belt systems)

Nitta Belt Series for Warehouse and Logistics

TA Series

Specifically developed for logistics applications, including TA12 black with smooth conductive surface for cross-belt sorters and rough SDLVR variants for live roller conveyors.

CFTG Series

Live roller belts with aramid fibre cores providing high tensile strength with 120mm long finger-splice joints for on-site installation.

(Reference to downloadable Nitta logistics brochure with full specifications)

Identifying the correct belt for your specific press doesn't have to be complicated. Our APR Conveyor Belts Belt Finder tool streamlines the selection process, helping you quickly locate the right belt based on your machine type, application requirements, and material specifications. Simply input your press details or upload a photo of your existing belt, and we'll match you with the optimal Nitta solution -ensuring you get the right belt first time, every time.

TESTIMONIAL

Paul and Alan have been supporting our site here in Newmarket for the last 25 years. Within this time we as a company have built up a fantastic working relationship and support network with APR. Which benefits our site not only with servicing contracts and breakdown cover but more importantly, the technical support, their knowledge and experience is only an email or phone call away. APR have been integral in our development of the new Pratham lines that our site has invested in, giving constant support when required. We all wish this collaboration to carry this site to the level.

MM Packaging UK Limited

Dave Dobbyn - Production Manager

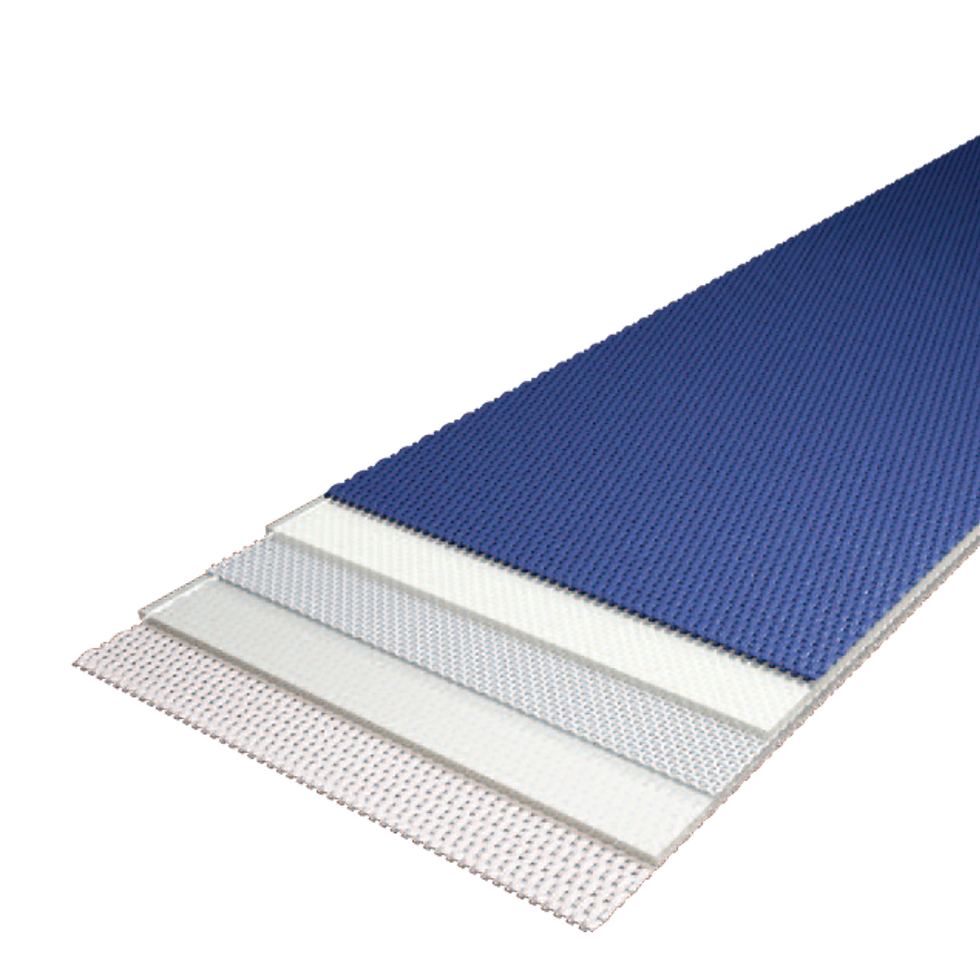

Belt Material Properties for Logistics

Warehouse and logistics applications demand specific performance characteristics:

Abrasion Resistance

Constant package contact requires belts that withstand wear, with Nitta belts offering up to 6 times longer life than competitor products through advanced compound formulations.

Load-Bearing Capacity

Handling varying package weights from small parcels to heavy boxes, requiring appropriate tension member construction.

Dimensional Stability

Aramid and polyester cores prevent stretching under load, maintaining consistent tracking and performance over extended service life.

Surface Properties Smooth surfaces for gentle package handling, or rough/ribbed patterns for incline applications requiring higher friction.

Conductive Properties

Anti-static formulations prevent static build-up in high-speed sortation systems, maintaining reliable barcode scanning.

Temperature Performance

Operating reliably across typical warehouse temperature ranges without degradation or loss of flexibility.

Conveyor Systems We Support:

We supply replacement belts for conveyor systems from major automation companies including Vanderlande, Swisslog, TGW, Dematic, Fives, Knapp, Honeywell and SSI Schäfer installations. Our engineering team cross-references existing belt specifications from these manufacturers, identifying equivalent or superior Nitta alternatives. Whether your facility uses Ammeraal, Forbo, Habasit, Chiorino or other competitor belts, we match your requirements with appropriate Nitta products.

Why Choose APR & Nitta for Warehouse Belts

Nitta Corporation has partnered with major warehouse automation companies worldwide, developing specialist belt series engineered specifically for automated logistics applications. As the UK's official Nitta Partner, APR Conveyor Belts combines this technical excellence with local expertise and rapid supply capability.

We understand that warehouse downtime costs money and disrupts delivery schedules. Our engineering approach means we solve problems, not just supply belts - we're here to keep your operation moving.

Typical Warehouse Applications

Conveyor belts are critical throughout automated warehouse operations:

-

Parcel Sorting Systems - High-speed sortation moving packages through scanning, weighing and routing operations

-

Distribution Centres - Main conveyor runs transporting goods from receiving to despatch areas

-

Order Fulfilment Lines - Moving picked items to packing stations

-

Cross-Docking Operations - Rapid transfer between incoming and outgoing shipments

-

Mezzanine Transfers - Incline/decline conveyors moving goods between levels

-

Loading Bay Systems - Telescopic conveyors for vehicle loading/unloading

Common Questions About Packaging Belts

Service life depends on operating conditions, package types, and belt material. In high-speed sortation with abrasive packages, belts might last 6-12 months. Moderate-duty applications with proper maintenance can see 18-24 months or longer. Nitta's advanced compounds typically outlast competitor belts by factors of two to three times.

Flat belt conveyors use the belt surface to transport packages directly. Live roller conveyors use belts running underneath to drive rollers, with packages sitting on the roller surface. Live roller systems require specialist belt constructions like CFTG series with aramid cores for the constant flexing around drive pulleys.

TGW systems typically use specific belt codes (e.g., TG series in various sizes). We cross-reference TGW specifications to Nitta equivalents - for example, TGW's Ammeraal TG belts at 660 x 800mm match our TA series. Provide us with your system details or existing belt code, and we'll identify the correct Nitta replacement.

Cross-belt sortation systems require smooth, conductive surfaces for accurate package diverting at high speeds. Nitta TA12 series with its smooth conductive finish and dimensional stability suits these demanding applications. The belt needs to maintain tracking accuracy whilst rapidly accelerating packages perpendicular to the main flow.

APR supplies replacement belts for Vanderlande conveyor systems. We cross-reference Vanderlande specifications to identify the correct Nitta equivalent, providing same-day or next-day delivery on common sizes. Contact our technical team with your system details, and we'll match the specification.

Warehouse Belt Resources

Download Nitta's comprehensive logistics belting catalogue featuring technical specifications, application guides and installation procedures for warehouse conveyor systems.

belt problems?

Distribution centre down? Sortation system stopped? Contact APR Conveyor Belts for expert belt identification, rapid supply, and professional installation services that get your warehouse operation back on track

WAREHOUSE & LOGISTICS INDUSTRY BELTS

Find Your warehouse Belt

Modern warehouse operations run on relentless schedules where a single belt failure can halt an entire distribution centre. Same day delivery promises and throughput targets measured in thousands of parcels per hour mean your conveyor systems face extreme demands, constantly varying package weights, high speed sortation wearing through standard belts in weeks, abrasive surfaces, static build-up disrupting scanners, and 24/7 operation with no room for downtime.

As the UK's official Nitta Partner, APR Conveyor Belts supplies replacement belts for automated warehouse systems, cross-referencing competitor specifications and delivering common types from stock.

Not sure which belt you need? Got a competitor's part number but need a replacement fast? Our APR Belt Finder tool helps you identify the right belt for your sortation system, live roller conveyor, or flat belt application in minutes. Enter your existing belt code from Habasit, Ammeraal, Forbo, Chiorino or other manufacturers, or tell us your conveyor system brand like TGW, Vanderlande, Dematic Fives Group, Knapp or Swisslog, and we'll cross-reference to the correct Nitta specification. If you know your belt dimensions or can send us a photo, we'll match it to the appropriate replacement. Can't find what you're looking for? Give us a call and we'll sort it for you.

.png)