CONVEYOR BELT SUPPLIER

UK's Nitta Approved Partner – Keeping Production Moving with the Right Belt, Fast

CONVEYOR BELTS

Find Your Conveyor Belt

Line down? Machine stopped? You need the right conveyor belt, and you need it now. We can identify the perfect belt for your application, deliver next-day on common stock, and get your operation back up without the long delays you'd face elsewhere. We're engineers who solve problems, not just belt suppliers - giving you the peace of mind that comes from working with people who've got your back.

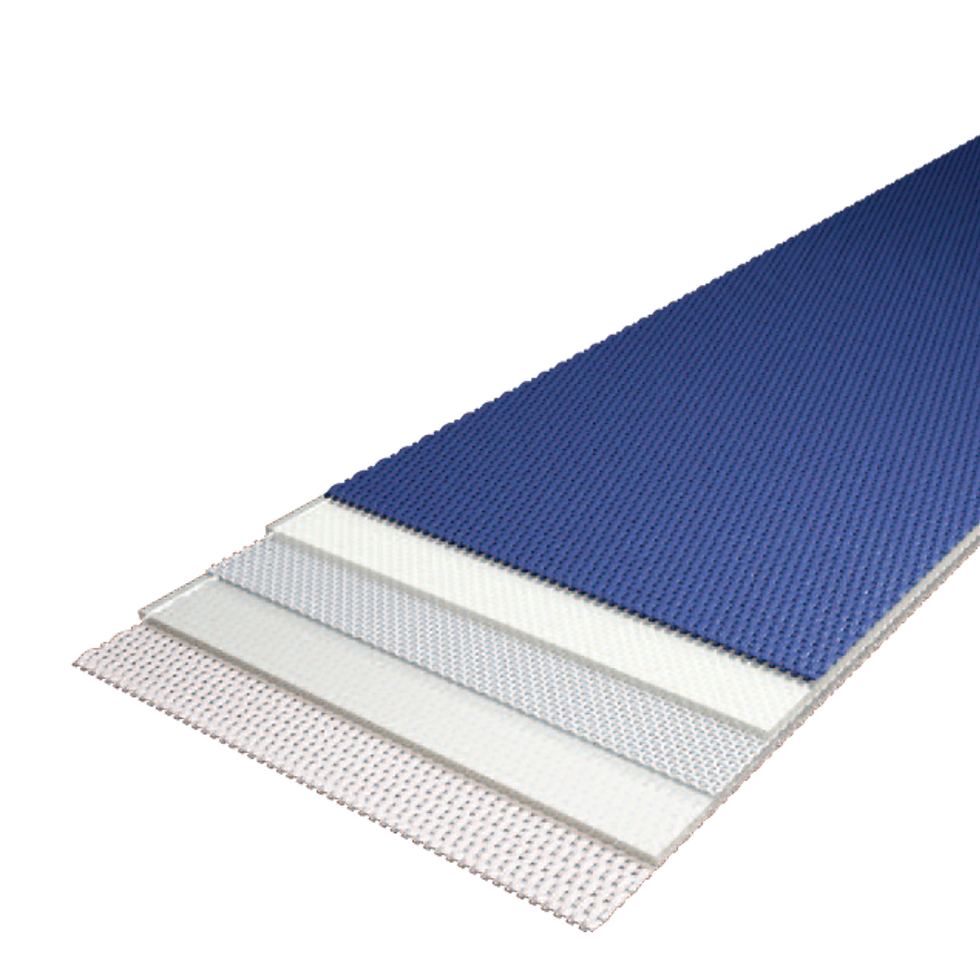

Conveyor Belt Materials

The material of your conveyor belt determines how it performs in your specific application. Different materials offer distinct advantages for grip, durability, chemical resistance, and operating temperature. Getting the material choice right means your belt lasts longer, runs reliably, and handles your products without damage.

FAQ's

Conveyor belts transport materials from one point to another, typically running on two pulleys with support rollers. Transmission belts drive machinery by transferring power between pulleys, often running around multiple pulleys on complex paths. Feeder belts specifically feed materials into machines, usually with features like perforations for vacuum suction or rubberised surfaces for grip. The distinction matters because each type is engineered differently - using the wrong type leads to premature failure.

Belt material selection depends on what you're transporting, your operating environment, and your performance requirements. For general warehousing and logistics, polyurethane offers the best all-round performance. Food applications need FDA-compliant materials. If you're handling oils or chemicals, material compatibility becomes critical. Temperature extremes, anti-static requirements, and food safety compliance all influence the choice. If you're unsure, tell us about your application and we'll recommend the right material specification.

Belt tracking issues usually stem from incorrect installation, misaligned pulleys, uneven roller wear, or a damaged shaft or bearing failure. Sometimes the belt itself is damaged or hasn't been properly tensioned. When we fit belts, we always track them in correctly and check for these underlying mechanical issues. Many belt failures blamed on "poor quality" are actually installation or maintenance problems. Getting it right from the start saves money and downtime.

Absolutely. Fire-retardant belts are essential for many applications, particularly in aviation, warehousing with high occupancy, and any environment where fire safety regulations apply. Nitta manufactures belts meeting various fire resistance categories, and we can specify exactly what you need based on your industry requirements and risk assessment. Just let us know your application and we'll ensure compliance.

For common belt types, we offer next-day delivery from our UK stock. For specialist belts or larger projects, lead times vary, but we'll always give you an honest timescale upfront. If you've got a line down and need an emergency response, call us immediately - we'll prioritise getting you running again.

Conveyor Belt Services

Getting the right belt is only half the battle – it needs to be fitted properly, tracked correctly, and tested to ensure it performs as it should. APR Conveyor Belts provides complete conveyor belt services beyond just supply. We'll come to your site, fit your new belt, track it in so it runs true, and test it under load to confirm everything's working.

Our engineers (not just belt fitters) also identify potential issues whilst they're there. Spot a bearing that's gone down or a shaft that's worn, damaged or failing? We'll flag it before it leads to another breakdown. We also offer ongoing maintenance support and technical advice whenever you need it – because we're interested in keeping your operation running smoothly long-term, not just making one sale.

TESTIMONIAL

CCL Label has built an outstanding relationship with APR over the past couple of decades. Not only have they consistently serviced and maintained our folding machines, but they are also quick to respond to emergency breakdowns—often arriving on-site within just a few hours.

Alan has played a key role in developing and training many of our strongest operators. Working with APR has allowed us to tap into decades of expertise, benefiting not only our bindery department but other areas of the site as well.

We look forward to continuing our partnership with Alan, Paul, and the entire trustworthy APR team for many years to come.

Dave Barton - Continuous Improvement Project CoOrdinator

CCL Label (Ashford) Limited

.png)